3 layer blown film extrusion

3-Layer Blown Film Extrusion: High-Quality Multi-Layer Plastic Films for Every Industry

In today’s manufacturing landscape, high-quality plastic films are essential for packaging, agriculture, medical products, and industrial applications. One of the most advanced methods to produce these films is 3-layer blown film extrusion—a process that combines precision engineering with material innovation to create films that are strong, durable, and versatile.

What is 3-Layer Blown Film Extrusion?

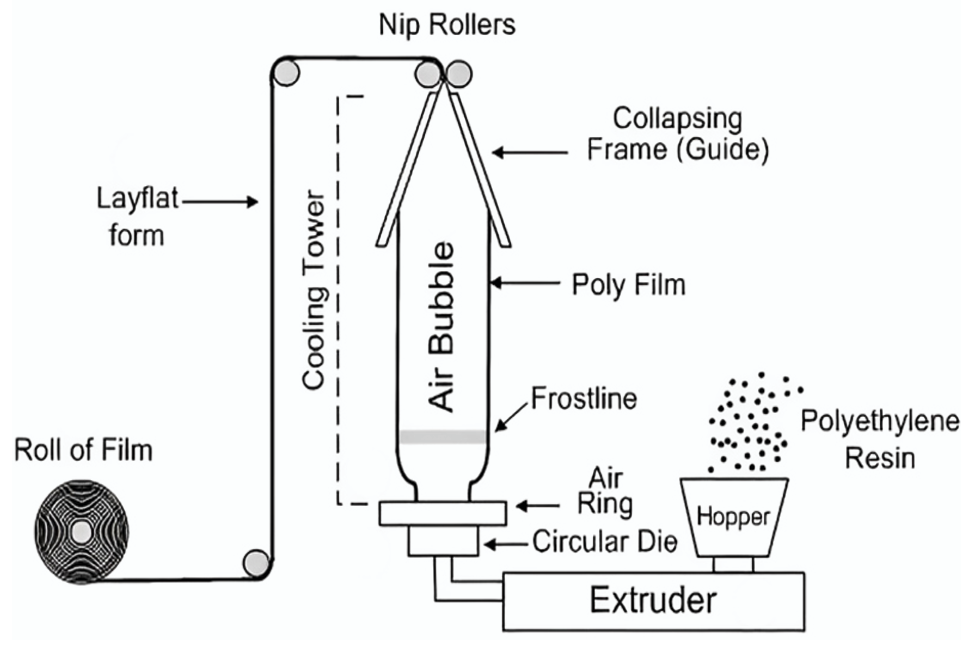

Blown film extrusion is a process where resin pellets are melted, shaped, and expanded into a thin-walled tubular film. Unlike traditional single-layer films, a 3-layer structure allows manufacturers to combine different polymers, giving each film custom properties:

-

Core layer: Adds strength and stability

-

Barrier layer: Provides resistance to moisture, oxygen, or chemicals

-

Skin layer: Optimized for printing, lamination, or surface finishing

This multi-layer approach results in multi-functional plastic films that outperform standard films in performance and reliability.

The Science Behind the Perfect Film

After extrusion, the molten tube—known as the “bubble” is inflated under precise air pressure and carefully cooled to lock in its properties. The bubble then collapses into flat sheets, forming a uniform, defect-free film ready for downstream processing. Every step, from melt temperature to bubble diameter, is tightly controlled to ensure consistent thickness and mechanical strength.

Benefits of Multi-Layer Plastic Films

Choosing 3-layer blown films comes with numerous advantages:

-

Enhanced durability: Stronger than single-layer films

-

Improved barrier properties: Protects contents from moisture, oxygen, and contaminants

-

Customizable functionality: Ideal for specialized applications like medical packaging or industrial wraps

-

Cost-effective: Reduces material use while maintaining performance

Applications Across Industries

3-layer blown films are used worldwide in applications including:

-

Food packaging and retail bags

-

Agricultural mulch films

-

Industrial liners and protective films

-

Medical and pharmaceutical packaging

Conclusion

3-layer blown film extrusion represents the future of high-performance plastic films. By combining material innovation with precision manufacturing, this process delivers durable, reliable, and versatile films that help businesses innovate and protect their products.

Whether for industrial use, food packaging, or specialized applications, multi-layer blown films are a smart, cost-effective choice for modern manufacturers.