Blown Film Extrusion Process – Step-by-Step Guide

Blown Film Extrusion Process – Complete Step-by-Step Guide

Blown film extrusion is one of the most widely used processes in the plastic packaging industry.

It is designed to produce high-quality polyethylene films used in carry bags, stretch film, shrink film, liners, and multilayer packaging applications.

01. Raw Materials

The process begins with plastic pellets such as LDPE, LLDPE, or HDPE loaded into the extruder hopper.

In 3-layer blown film plants, different materials are used to achieve specific film properties like strength, flexibility, and sealing performance.

02. Extrusion

Inside the extruder, the plastic pellets are heated and melted by a rotating screw. The molten plastic is filtered and pushed through a circular die.

- Multiple extruders combine materials for multilayer film

- Improved mechanical strength

- Enhanced film performance

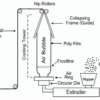

03. Inflation (Bubble Formation)

The molten plastic exits the die and is inflated with air to form a bubble. This stage determines the film’s thickness and width.

04. Cooling & Collapsing

The bubble is cooled using an air ring system to stabilize the film structure. After cooling, the bubble is collapsed into flat film using guiding frames.

- Improves clarity and strength

- Maintains film stability

- Prepares film for winding

05. Winding

The flat film is wound onto rolls using a fully automatic two-station surface winder for continuous production without downtime.

Maximum Lay Flat Width: 2700 MM

Maximum Output: 650 Kgs / Hr

Why Choose a 3-Layer IBC Blown Film Plant?

- ✔ Auto Film Thickness Control

- ✔ Imported IBC Control System

- ✔ Fully Automatic Two Station Surface Winder

- ✔ Gravimetric Dosing with Throughput Control

- ✔ High Output & Energy Efficient